Why Aluminum Foundry Techniques Are Reshaping Modern Manufacturing

Wiki Article

Understanding Metal Casting Processes: Innovations and Patterns in the Foundry Industry

The foundry market is experiencing substantial improvements driven by technological advancements. Developments such as 3D printing and man-made intelligence are improving steel casting procedures, improving efficiency and precision. Lasting practices are obtaining grip, emphasizing the significance of ecological duty. On top of that, the intro of sophisticated materials and automation is boosting general casting top quality. These growths recommend an essential shift in the market, increasing inquiries regarding future directions and implications for manufacturers.Improvements in 3D Printing for Metal Casting

Recent innovations in 3D printing modern technology have considerably transformed the landscape of steel casting. The combination of additive production strategies has made it possible for the quick production of complex patterns and mold and mildews that were previously tough or impossible to accomplish with typical techniques. By utilizing materials such as sand and steel powders, suppliers can create elaborate geometries that enhance style adaptability and lower material waste. This advancement not just expedites the prototyping process however likewise permits the customization of components tailored to certain applications.

3D printing assists in shorter lead times, which is vital in industries requiring fast turn-around for parts. The technology additionally sustains the manufacturing of light-weight structures, thereby boosting energy effectiveness in final result. Consequently, the foundry sector is experiencing a change towards more lasting methods, driven by the efficiency and precision provided by these contemporary 3D printing methods in steel casting processes.

The Function of Artificial Intelligence in Precision Manufacturing

As markets increasingly take on advanced manufacturing modern technologies, expert system (AI) is playing a critical function in boosting precision production processes. AI formulas assess large datasets to maximize and recognize patterns manufacturing parameters, leading to boosted accuracy and efficiency. In metal casting, AI aids in anticipating maintenance, decreasing downtime by projecting devices failings before they take place.AI-driven simulations allow makers to model the casting process, refining layouts and decreasing issues. Artificial intelligence strategies improve quality assurance by discovering anomalies in real-time, thereby making sure that just products meeting strict requirements proceed via the assembly line.

Lasting Practices in the Foundry Market

Sustainability has actually become a critical focus in the foundry industry, prompting producers to take on techniques that decrease ecological impact while preserving performance - Metal Foundry. One prominent strategy consists of the recycling of materials, especially steels, which significantly lowers waste and power usage. Shops are significantly implementing closed-loop systems, enabling the reuse of sand and other casting materials, thus decreasing the demand for virgin sourcesOn top of that, energy-efficient technologies, such as electric heaters, are obtaining traction, as they reduced greenhouse gas exhausts contrasted to conventional methods. Numerous factories are exploring the usage of green finishings and biodegradable binders to decrease toxic byproducts. Employee training on lasting methods has likewise come to be necessary, promoting a culture of environmental duty within organizations. Generally, these lasting methods not only contribute to ecological conservation but additionally improve the lasting stability of the foundry industry in a progressively eco-conscious market.

Technologies in Materials for Enhanced Casting Quality

With the continuous advancement of the foundry sector, innovations in products have actually become crucial for boosting casting quality. Advanced alloys and composite products are significantly being used to enhance mechanical buildings and decrease defects in spreadings. These materials typically provide premium strength-to-weight proportions and boosted resistance to deterioration and wear, dealing with the demands of modern-day applications.In addition, the unification of nanomaterials is obtaining traction, enabling finer microstructures that bring about boosted surface coatings and dimensional precision. Aluminum Casting. 3D printing technologies likewise contribute in generating complicated geometries with very little waste, allowing the usage of customized materials that were previously challenging to cast

Furthermore, the growth of ecologically pleasant binders and additives adds to lasting practices while maintaining premium end results. Jointly, these technologies not just improve the performance of actors products but likewise align with the market's change towards sustainability and performance.

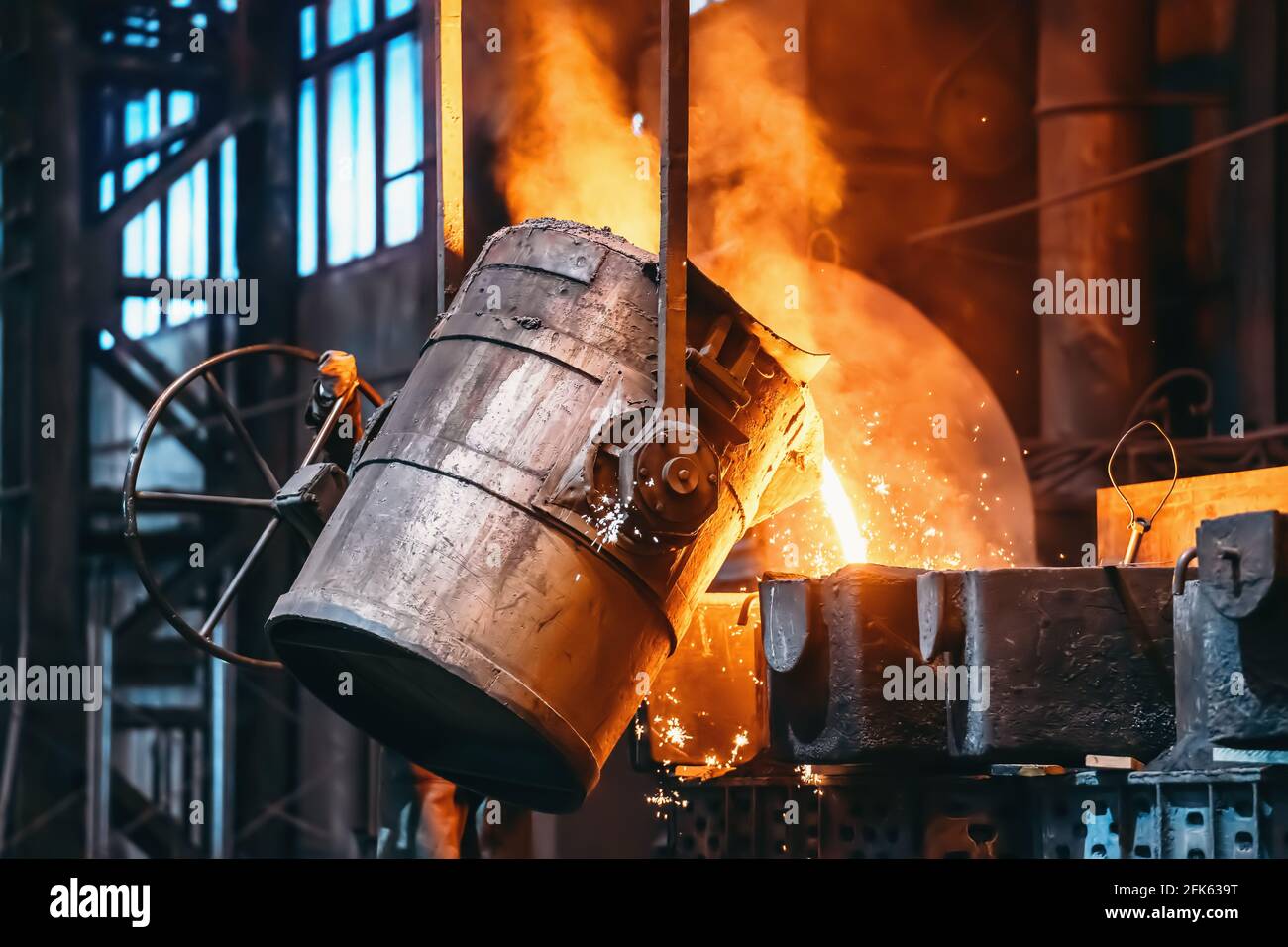

Automation and Robotics in Metal Casting Processes

Automation and robotics are revolutionizing metal casting processes by enhancing procedures and improving precision. In modern-day shops, robotic systems are used for tasks such as mold handling, pouring, and finishing, significantly lowering human intervention. This not just decreases the risk of crashes yet likewise ensures constant top quality in manufacturing.Automation technologies, such as computer mathematical control (CNC) devices, promote intricate layouts and intricate geometries that were previously challenging to accomplish. Real-time information analytics enable manufacturers to check processes and maximize efficiency constantly.

The combination of automation results in boosted productivity and effectiveness, allowing shops to satisfy growing market demands while minimizing preparations. As the industry embraces these advancements, the labor force is likewise evolving, calling for new abilities website link to operate and keep advanced equipment. Generally, the fostering of automation and robotics is a crucial trend shaping the future of metal casting processes.

Frequently Asked Inquiries

What Is the Background of Metal Casting Strategies?

Metal casting techniques day back to ancient human beings, with proof of bronze casting in Mesopotamia around 3000 BCE. Over centuries, approaches evolved significantly, integrating innovations in products and innovation, shaping modern-day commercial practices.How Does Metal Casting Influence the Setting?

Metal casting considerably influences the environment via energy consumption, exhausts, and waste generation. Nonetheless, advancements in lasting methods and innovations aim to minimize these effects, promoting even more eco pleasant techniques within the market.What Safety And Security Steps Are Crucial in Foundries?

What Are Typical Flaws in Metal Casting Products?

Usual issues in steel casting items consist of porosity, contraction, misruns, cool shuts, Full Article and surface imperfections. These issues occur from elements such as incorrect temperature control, inadequate mold design, and contamination throughout the casting procedure.Just How Do Foundries Make Certain Quality Assurance in Casting Processes?

Shops carry out strenuous high quality control procedures with regular evaluations, standard screening, procedure surveillance, and adherence to industry criteria. These techniques aid determine flaws early, making sure the stability and dependability of the last casting items.Advancements such as 3D printing and man-made intelligence are improving steel casting procedures, enhancing performance and precision. Current improvements in 3D printing innovation have actually significantly transformed the landscape of steel casting. Automation and robotics are transforming steel casting procedures by improving and simplifying procedures precision. Metal casting techniques day back to old civilizations, with evidence of bronze casting in click over here Mesopotamia around 3000 BCE. Common defects in steel casting items consist of porosity, contraction, misruns, cool shuts, and surface area flaws.

Report this wiki page